In the face of what is quickly becoming an energy crisis, Teagasc advisors take a look at solutions that could safeguard the future of the horticulture industry.

Energy costs have increased significantly due to external macroeconomic factors, but more recently due to the invasion of Ukraine. The horticulture sector has for some years been moving away from fossil fuels and micro generation by wind turbines has fallen out of favour. Solar, biomass and heat pumps are likely to dominate in the future.

SOLAR PHOTOVOLTAIC (PV) Investing in Solar PV is becoming more and more attractive for horticulture producers. Solar PV panels generate electricity from daylight, although they produce most in direct sunlight. Solar PV can be supplied as panels or tiles and can be built into the fabric of a building, bolted on afterwards or built on a frame on the ground. An inverter is needed to convert the direct current (DC) electricity output of the PV panels to alternating current (AC) for immediate use or to charge batteries.

In general, solar PV needs 7-8m2 per kilowatt (kW) of installed capacity. A 50kW roof mounted array would need approximately 400 square meters. This 50kW unit could generate as much as 45,000kWh of energy per annum. By offsetting 45,000kWh of electricity, this is a potential electricity saving of €15,750 per year for a producer (based on current estimated average electricity unit rate of €0.35/kWh). This varies depending on the site location (the South East receives the highest levels of solar radiation in Ireland) and direction the roof is facing. Approximately three quarters of the energy will be produced from April to September. PV panels have very low regular maintenance requirements; a visual check for debris by the owner on an annual basis is usually sufficient.

Donal Gernon (Teagasc Mushroom Advisor) spoke to Peader McGee, who is owner of Cornacrieve Mushrooms regarding their investment in Solar PV: “We installed 50kW of Solar PV in 2018 and an additional 35kW in 2020. It works perfectly on my farm, as the PV generates the bulk of electricity at times of the year when we need it the most for cooling purposes. I intend to invest in more solar PV next year to ease the burden of rising electricity costs.”

If you are generating more energy than you are using and your PV system is connected to the grid, the balance will be exported but you will not receive payment at present, although this is expected to change. It is worth noting that displacing your own energy use is worth more to you than exporting. Therefore, solar energy systems work best if you have a daily energy use to balance your generation so that you can consume the energy you generate.

Horticulture growers in producer organisations can avail of 50% grant aid on a solar PV investment through the On Farm Investment (OFI) scheme. Growers who are not in a producer organisation can get a 40% grant through the Horticulture Grant Scheme. With this level of grant aid, producers can have a relatively short return on investment (under 3.5 years) which makes this renewable technology very attractive. There are also some tax advantages with Accelerated Capital Allowance reliefs. Solar PV will certainly ease the burden of rising electricity costs and ultimately reduce the cost of production for producers.

BIOMASS HEATING SYSTEMS

Many horticulture producers have adopted biomass as their main source of fuel for heating their production units. Biomass fuel material can consist of wood chip, wood pellet, straw or waste organic material. Wood chip and pellets are more commonly used in large boilers (50kw-1MW). Biomass boilers have been successfully used for heating for many decades and are a proven technology. Biomass heating systems can be used for space heating, hot water production, steam production, or a combination of these uses.

There are still many horticulture enterprises who are still using a fossil fuel source for heating. The Support Scheme for Renewable Heat (SSRH) is a scheme that provides operational support for biomass boilers and anaerobic digestion heating systems. The objective of the scheme is to replace fossil fuel heating systems with renewable heating technologies to contribute to meeting Ireland’s renewable energy targets whilst also reducing greenhouse gas emissions. This scheme is of huge interest to the many horticulture protected crop producers as there are large heating requirements on these units. Unfortunately, this scheme will only apply to businesses converting from oil/gas to biomass. Many farms and nurseries are already heating with biomass and will not qualify for the scheme. Growers who are expanding or growers who are using oil in combination with biomass will be considered for the scheme as there is the opportunity to displace the use of oil or gas. For successful applicants who are accepted into the scheme, a quarterly tariff payment is paid to growers based on heat output.

For many mushroom growers, applying for the scheme and converting to renewable technologies is an easy decision given the significant savings to be made through SSRH operational payment. There is also likely to be a fuel cost saving as oil and gas prices have increased sharply over the past 12 months. For example, at current fuel prices, a typical mushroom unit using 60,000 litres of Kerosene per annum has the potential to save over €21,889 each year on fuel costs by switching to biomass wood pellets. The farm would also be entitled to an SSRH operational payment of €25,141 per annum based on heat output for the farm of 570MWh. In total the farm would save €47,030 per annum by switching from an oil boiler to biomass heating boiler.

Investing in a biomass boiler would result in a relatively short return on investment that makes the scheme a no brainer for many horticulture producers. In terms of carbon footprint, businesses will significantly reduce CO2 emissions. For the mushroom unit displacing 60,000 litres of kerosene per year, this reduces CO2 emissions produced by 140 tonnes. Actions like this will substantiate your farm’s sustainable credentials. Gareth McKenna (Director of McKenna Mushrooms) said: “The SSRH application was an extensive and lengthy process, however when we received our first quarterly payment we saw the financial benefits of the scheme and how it will be a huge saving for us in the future.’’

The supply of biomass in Ireland has developed in the last ten years. The Wood Fuel Quality Assurance (WFQA) scheme was started by the Irish Bioenergy Association in 2009. They certify their members for compliance with ISO 1722. There are currently 35 members in the scheme. An alternative approach that some growers use is to pay for the heat that the wood generates so there is no requirement to monitor the moisture content etc. of each delivery.

All these factors make the SSRH scheme more attractive and sensible from a commercial point of view. For those interested in applying for the scheme, you can start the application process by submitting an online application form on the SEAI website.

HEAT PUMPS

Heat pump technology at its simplest takes heat from one source and uses an electric powered pump to extract it and send it to another area. This basic model can be used to cool, similar to a fridge, or to heat a domestic home. There has been a large push towards these systems for domestic use as they can be powered by sustainable sources of energy at relatively low cost.

At commercial scale, heat can be drawn from the ground, water sources including lakes, deep wells, and air. Multifunctional Heat Pumps are newer technologies becoming common in buildings where they can cool one area and heat another using heat pumps and buffer tanks. Some of the most substantial developments in horticulture make use of waste heat from data centres to heat glasshouses.

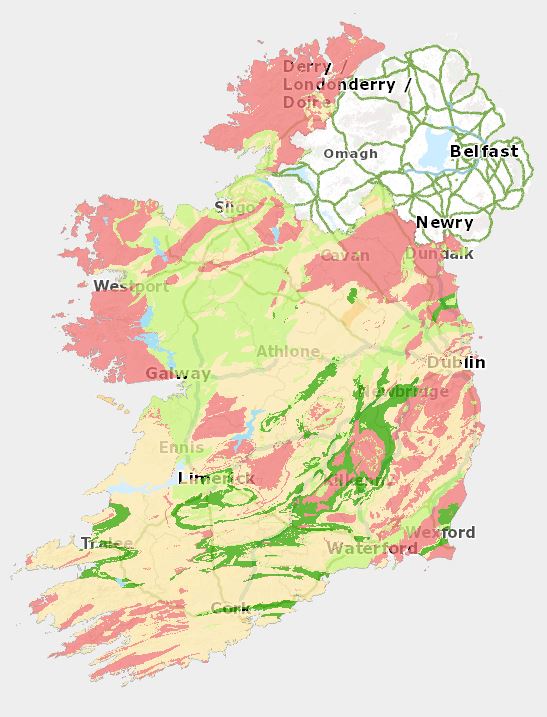

The Netherlands, as the main innovator of horticulture in Europe, have developed numerous deep ground source heat pumps. Geothermal heat is reported to provide about twelve percent of their annual heat requirements for horticulture. These deep wells are tapping into temperatures of over 750C at a depth of 2km. In Ireland we have suitable sites with warm water closer to the surface e.g. Mallow and Leixlip. The Geological Society of Ireland are developing resources for the sector. Growers and home owners can view maps of the suitability of their locality for ground source heat pumps. See www.gsi.ie.

HORTICULTURAL APPLICATIONS

The heat generated by the pumps is commonly used in hot pipe systems. The water temperature is typically low, in the region of 20- 30°C, but can achieve 50-60°C. New technologies can see much higher temperatures and can be topped up using an electric immersion if higher temperatures are required e.g. for washing. Common uses of the heat are for heated glasshouse crops and underfloor heating for propagation and bedding plant production. As mushroom crops are staggered to provide ongoing harvesting the sites often require heating and cooling at the same time. The image below shows the installation of underfloor heating at Swantons Nursery, West Cork, that is heated using an air source heat pump. Trevor Swanton says “The system really comes into its own once day length increases after St. Patrick’s day. We find crops are turned over much more quickly and root growth is great.” Trevor is happy with the system and quality of the plants grown on it and believes there could be more fine tuning done to refine it.

MEASURING THE SUITABILITY OF HEAT PUMPS FOR HORTICULTURAL USE – COEFFICIENT OF PERFORMANCE

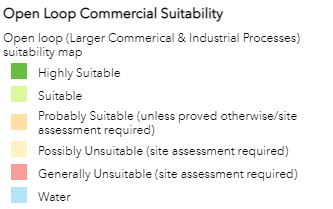

The process requires energy to drive it (typically electricity to run the compressor). However, for each unit of energy to drive the process, more units are captured and delivered. The ratio of energy delivered to energy input is referred to as the coefficient of performance (COP). Some typical values for the different sources are shown in the table.

The COP of heat pumps is greater if the temperature difference between source and delivery temperatures is less. This explains why a ground source heat pump is more efficient over a heating season than an air source heat pump, which extracts energy from the air that is often at lower temperatures than the ground. A COP of 4 represents a production of 4kWh of heat at the condenser for an input of 1kWh of electricity at the compressor. Typical COP of sources are; air 3.5, ground 4 and water 4.5.

Sizing of systems to match demand is essential. The more closely this can be matched the better, as capital costs tend to go up pro rata with size (unlike gas or oil boilers for example). The size of the collector has to be calculated accurately also to ensure that the system performs well – too small and it won’t work efficiently and too big will lead to unnecessary capital spend. The nature of ground type will impact costs and sizing also – wetter soil/rock types in general have higher heat reserves and require less pipe work resulting in cost savings.

SUPPORTS FOR RETROFITS OR NEW SYSTEMS

The Support Scheme for Renewable Heat (SSRH) installation grant for heat pumps supports ground, air, and water- source electric heat pump installations, with grant aid up to thirty percent of the capital outlay. The Scheme of Investment Aid for the Development of the Commercial Horticulture Sector offers forty percent grant aid for capital investments, which include energy-efficient and renewable energy technologies. When calculating financial viability, it is important to factor in the offset cost of an alternative heating system, such as a gas boiler (and possibly the laying of a gas supply or installation of an oil tank – if the alternative is oil) see table above. Heat pumps look much more viable where there is a cooling demand and their capital cost can be spread over the heating and cooling savings.

As experience and skills of installation develop and conventional energy costs continue to grow, the case for sustainable sources of energy and heat will become more compelling. Nationally we are committed to reducing our dependence on fossil fuels. The technology identified here already appears to make financial sense and is good for the environment too.

See the Teagasc website for webinars and factsheets on energy options. ✽

DÓNALL FLANAGAN is a nursery stock/ ornamentals specialised Advisor working with the Teagasc Horticulture Development Department in Ashtown. He has been working with Teagasc since 2007 and in his current role since 2016.

|

DONAL GERNON is a Specialist Mushroom Advisor with Teagasc. Donal provides technical assistance to all mushroom growers in Ireland and keeps growers updated on new mushroom picking technologies.

DONAL GERNON is a Specialist Mushroom Advisor with Teagasc. Donal provides technical assistance to all mushroom growers in Ireland and keeps growers updated on new mushroom picking technologies. BARRY CASLIN has been the Teagasc Energy and Rural Development Specialist since 1998.

BARRY CASLIN has been the Teagasc Energy and Rural Development Specialist since 1998.