Teagasc nursery stock/ornamentals advisor, Dónall Flanagan reports from IPM Essen and recent nursery study tour to the Netherlands and Germany

This was the first Teagasc nursery stock study tour after an absence of a few years. The focus of the tour is to introduce growers to new and innovative nurseries and take in IPM Essen. There were eight participants – a mixture of growers, suppliers, and lecturers. The tour took place from 23 to 25 January, traveling from Dublin to Düsseldorf. Weather for the duration of the visit was about a freezing point. The tour was organised by Dónall Flanagan.

Visiting six nurseries, one garden centre, one trade show and one trolley fair was very rewarding, not to mention good fun.

Over three days we set out to see a range of nursery styles from young to finished plants, trees, shrubs, and bedding. I had a few tips on places to visit and had seen one or two previously, and they were mostly very impressive. All sites were in the Venlo region of the Netherlands and Kempen region in Germany.

Overall the impression from the sector is mixed. There is some concern about Brexit and the biggest tree nursery in Europe (just down the road) going into liquidation last October. We were told there are simply too many trees on the market. On the positive side, bedding and young plant growers were upbeat and this was evidenced by increases in glasshouse investment.

DAY ONE: BOOMVELT DEN MULDER

Our first visit was to Boomvelt Den Mulder, a 200ha tree nursery producing trees from 8-10 to 35+. As winter daytime temperatures were only between -3oC and +2oC for about six weeks, no lifting was being carried out at that time. Plants had been lifted in November, rootballed and covered in straw to protect them. Another knock on of the cold weather was that it was too cold for customers to plant, so no deliveries were being made. The result will be a major bottleneck in March. At the time of visiting they were only able to prune and cane. Noel Kinsella noted, “It was interesting to see their approach to pruning their stock,” which was very tight. Rodge, who showed us around, explained the production cycles and sales aspects. Multistem trees are a key product. Trees are budded or grafted in their glasshouse and then replanted every two years in the field depending on vigour. Slow growing lines are grown on their own land. The land is rented at €2,000 per year so there is a need to get trees in and out as quickly as possible. Rodge pointed out that his Dutch clients were happy with three separate plants used as a multistem but that French clients wanted one true multistem plant. Den Mulden is launching a webshop this spring which will be available to the public and trade to purchase from. Web shops were a common feature of other nurseries visited.

Treevention is a local trolley fair in Venlo with about 30 exhibitors. I believe we were not the only Irish visitors there, a free lunch is sure to bring in a crowd. The trolley fair was organised a little differently to our own. Exhibitors have their

“Interesting to see that a Ryanair version of a garden centre can work when the market gets saturated with garden centres that all offer more or less the same” Paul Fitters |

own pitches as in a fair and plants are displayed over a bigger area on sloping shelves at ground level. It encouraged more browsing than having plants on trolleys. Another key difference was that the fair was held on Sunday and Monday in a warehouse.

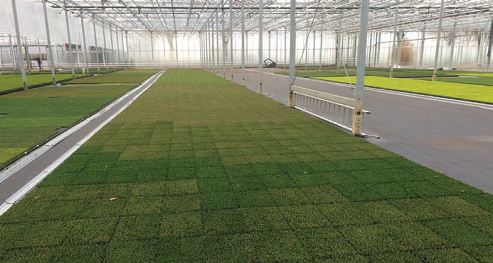

We met Bernt Rotjes that afternoon, who set up a young plant nursery while he was in college. Some 20 years later, he and his brother are producing 40m plugs a year from a 20,000 m2 glasshouse. Before visiting I was told he produced some of the best young plants in the world and after visiting I knew why. The attention to detail was exceptional. Liam McMahon noted he was “impressed with the obsessive attention to detail throughout the nursery and the nearly spotless glasshouse production areas – weeds and liverwort were unseen”. Everything had a place and was stored when not in use. Small things added to the overall picture. Cutting material was handled in small plastic crates, washed daily and sterilised weekly. Plugs were protected from compaction while striking cuttings etc. Every aspect of the production was refined to be clean and quick. Some machines such as mechanical weeders for the field stock plants and trimming and vacuuming machines were designed and built specifically for their site. Each tray had a RFID tag, these are scanned by passing a boom over them. One bay takes less than a minute, an inventory of the whole site is completed in less than four hours. The propagation room has space for about 45 people to work at its peak in during the summer, but there were just 14 there as we visited. Labour is mostly done by regular seasonal workers and Rotjes supplies accommodation in the local village.

A common feature that became apparent as we visited different sites was that much cutting material was imported e.g. from Kenya and South Africa. One grower had sent their own licensed stock to South Africa and cuttings were sent back exclusively to him. Seasonal availability and good quality control in these countries have made this not just cost-effective but essential for the increasingly early bedding and young plant season. Fast and reliable transport is an essential part of this process. Being near Schiphol and Dusseldorf is advantageous.

DAY TWO: IPM ESSEN

I had been told for a long time IPM Essen is the must-visit trade show in Europe and one day isn’t enough. That’s right on both accounts. Our group spent Tuesday at the show. IPM Essen is vast with about 12 large halls; my phone told me I walked up to 12,447 steps or 7.2 km, and there was plenty of browsing and chatting along the way. It was great to see Irish companies like Kelly’s, FitzGerald’s, Bord na Mona and Forest Fresh Christmas Trees competing on an international stage. As with any trade show, they are of most use if you go with a purpose in mind. If you feel you get overlooked when emailing or calling suppliers in Europe you have their attention here and get plenty of information. I was most impressed with the new lines of plants being launched at the show which was only a small part of it. There just wasn’t enough time to see it all.

DAY THREE: GÜNTER AND SUSANNE VAN SOEST

Our first site visit on the following day was to Günter and Susanne Van Soes. They are significant producers of seasonal plants less commonly seen in Ireland. Their main crop is Lantana camara that starts in week 24 and they being to sell half grown plants from week 8. This is ideal as it make space available at just the right time. Finished plants sell from week 14 and peak at week 16. All plants will be gone by week 30 when the new crop cycle begins. They have developed their own 11cm colour pot ‘Happy Plants’ range. Plants are watered by flooding concrete floors as needed, taking 12 minutes to fill, soak and drain. Pests and diseases are managed by starting with clean stock. Silwet Gold is applied to all new plants to kill all pests. This is followed up with regular Naturalis L sprays and widespread use of yellow sticky strips. The quality assurance scheme EuroGap is used for looking at records, pesticides etc but it doesn’t look at the plant quality. Again, we were very well cared for by our hosts, though no one able for the beer was on offer first thing in the morning!

WARREN EVENS, NOEL KINSELLA, ROSS MCMAHON, JOHN RYAN, DÓNALL FLANAGAN, PAUL FITTERS, ROB JACOBS, ADRIAN BYRNE

LIAM MCMAHON, SUSANNE VAN SOEST, NOEL KINSELLA, WARREN EVENS, PAUL FITTERS, JOHN RYAN, ADRIAN BYRNE, ANNAGRET KRAUSE, GÜNTER VAN SOEST, ROSS MCMAHON

Next up it was father and son operation Flores in Terra, specialising in tropical plants. Albrecht Brand started growing tomatoes but then looked to grow ornamentals in a less competitive market. Stan, his son, has since joined the nursery and together they grow a wide range of tropical plants that are fairly hardy e.g. Musa, Dicksonia, Rhaphiolepis and some novel food crops such as lemongrass and Stevia. Customers are mostly large garden centre chains but sales are also supported by a completely separate company selling online. This company calls in and collects as their sales require and Albrecht bills him weekly for what they buy. Paul Fitters noted, “It shows that specialising can pay off [in The Netherlands] and results in having a more varied nursery and workload, but in the case of tropical plants risky too, as the heating cost can be enormous in winter”. The week previous to our visit, a night of -8oC had cost €1,200 in heating.

One of the most innovative sites visited was a garden centre, Jacobs Budget Plant. Rob Jacobs was a nursery producer on the edge of Venlo town. He converted to a garden centre some years ago but found that there was an opportunity to differentiate. His USP is lower price plants, with ‘Always Better Value’ on the trapline. He now only sells plants and pots. There is a separate café on site. The garden centre has reduced labour costs as much as possible. Planograms are available for each bench and these are planned up to a year in advance. He has developed a number of webshops and has set his price point to make a 7% lower margin than his competitors. When purchasing plants Rob’s’ first criteria is quality and secondly price. It might sound lofty, but to be honest I couldn’t fault the quality of the stock we saw there. Jacobs Budget Plant has one person running the websites and his own team making deliveries within an hour’s drive of Venlo. The online team will grow by two people this year. The websites use search engine optimisation such as Google Adwords, Facebook ads etc to promote the business. Paul Fitters commentated that it was “interesting to see that a Ryanair version of a garden centre can work when the market gets saturated with garden centres that all offer more or less the same”. There are daily sales reports compiled for 50 garden centres in the Netherlands and Jacobs Budget Plant is now consistently in the top five. The costs of the investment haven’t yet been returned in online sales; however, footfall to the garden centre was up 30% last year.

Our last two sites were poles apart. Leenders is a family run nursery producing mostly ground cover and conifers for the eastern European market. They had some very nice trials of Hebe combinations in bowls. Unusually, plants were packed in crates for dispatch, perhaps something that would not be done at warmer times of the year. Boeker focusses on plug production of bedding plants from cuttings, again sourced in Kenya. This site was the least mechanised we visited with a high reliance on migrant labour, with Boeker providing accommodation and transport for their employees.

We were all struck by the levels of openness and hospitality from the nurseries we visited. Liam McMahon commented, “I was very impressed that they shared so much information

freely and gave such great hospitality”. We got a great reception everywhere we visited. Fly cake is much nicer than it sounds. Soup, sandwiches, and beer were all on offer so no

one went hungry. We saw that the growers have some issues similar to ours, logistics and cash flow are essential to make a business successful and can overcome even a difficult climate. The take-home message was that most growers were happy to meet other growers and share information. We just need to go meet them. ✽

Ashtown, serving the nursery stock and ornamental sector.Dónall Flanagan, Ashtown Food Research Centre

Mobile: 087 703 5823; Tel: 076 111 4021

Email: donall.flanagan@teagasc.ie